top of page

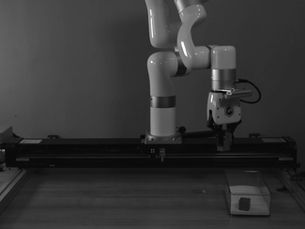

Robotic Arm Automation

Learn how robotic arms power automation, from streamlining repetitive tasks to enabling flexible production with the latest technologies and safety standards.

Soft Grippers: The Future of Flexible Robotics

For teams in manufacturing, warehousing and automation at Blue Sky Robotics, the rise of compliant robotic end-effectors marks a practica l shift toward safer, more adaptable handling of delicate or irregular items. A soft gripper relies on flexible materials, compliant mechanisms and integrated sensing to conform to shapes and absorb contact forces, which reduces product damage and improves human‑machine interaction compared with traditional rigid grippers. Demand for gentl

3 min read

Articulated Define: Understanding Articulated Robots in Automation

Articulated robots are multi‑jointed manipulators whose rotary joints mimic the motion of a human arm; in industrial automation, “articulated” describes that jointed structure and the resulting degrees of freedom that enable complex, multi‑axis motion. This jointed design gives articulated robots a valuable combination of flexibility and precision, allowing them to perform tasks such as welding, assembly, material handling and machine tending with repeatable accuracy. As fac

3 min read

Mechanical Arms in Action: Driving the Next Wave of Automation

Mechanical arms have become a cornerstone of modern robotics and automation, reshaping production lines and warehouse operations with unprecedented speed and accuracy. These systems marry precision engineering, artificial intelligence, and adaptable design to streamline workflows, reduce error rates, and enable new forms of flexible manufacturing. For Blue Sky Robotics’ audience in manufacturing, warehousing, and automation, understanding this convergence is essential to plan

3 min read

Understanding the Meaning of Articulated Systems in Robotics

Articulated robots, machines built from multiple rotary joints, offer the multi-axis motion that brings both precision and adaptability to automation tasks. For manufacturers, warehousing operators and automation integrators at Blue Sky Robotics , understanding articulated systems in robotics clarifies why these platforms excel at complex assembly, material handling and inspection. Their jointed kinematics let end effectors reach around obstacles and execute finely tuned path

4 min read

Inside the Anatomy of a Robotic Arm: Understanding Its Core Parts

Inside the anatomy of a robotic arm, these devices have advanced from simple pick-and-place mechanisms to sophisticated systems that now shape modern automation and manufacturing. Fo r Blue Sky Robotics’ audience, manufacturers, warehouse operators and automation specialists, understanding that evolution helps pinpoint where to invest in hardware and process improvements. This topic matters now as demand for faster cycle times, tighter tolerances and more flexible automation

3 min read

Understanding Payload Capacity in Robotics and Automation

Payload capacity determines the maximum mass a robot can handle while still meeting performance, safety and longevity requirements. For manufacturers, warehouses and automation integrators working with Blue Sky Robotics , understanding payload capacity in robotics is essential for selecting arms that deliver the necessary reach, cycle time and reliability without compromising safety or efficiency. This post examines the factors that influence rated versus usable payload, pra

4 min read

Navigating Robotic Structured vs Unstructured Pick and Place

Robotic pick and place systems have become a foundational automation element across manufacturing, warehousing and logistics, where speed, consistency and safety are paramount. These systems range from simple conveyor-fed grippers to advanced robotic cells, and they help organizations reduce labor costs, improve throughput and maintain quality at scale, outcomes that matter to Blue Sky Robotics’ audience. Comparing robotic structured vs unstructured pick and place clarifies

4 min read

Cobots Explained: How Collaborative Robots Are Transforming Workspaces

Collaborative robots are designed to work side-by-side with human employees, using compact form factors, force-limited joints, and advanced sensing to prioritize safety and flexibility over the heavy, enclosed designs of traditional industrial robots. Unlike conventional automation that isolates people from machines, a cobot is built for shared workspaces and simpler programming, enabling tasks that require human judgment or dexterity to be augmented rather than replaced. For

4 min read

Unpacking the True Definition of a Robot

Explore what defines a robot versus a traditional machine, from sensing and autonomy to AI-driven adaptability, and see how these distinctions shape robotics in industry and healthcare.

4 min read

Understanding Magnetic Grippers for Industrial Automation

Magnetic gripping solutions are playing an increasingly prominent role on the factory floor as automation expands into more diverse handling tasks. End-effectors are the robot’s point of contact with parts, and their design determines throughput, repeatability and safety for material handling, assembly and machine tending; for Blue Sky Robotics’ audience in manufacturing, warehousing and automation, understanding when to deploy a magnetic gripper versus other options is essen

4 min read

Understanding Payload Capacity in Robotics and Automation

As robotics and automation systems become core to modern production and logistics, understanding how much weight a robot can safely and reliably handle is essential. In practical terms, payload capacity in robotics refers to the maximum mass a robot or automated device can carry, move and manipulate while maintaining performance and precision. That capacity directly shapes cycle speed, reach and the range of tasks a system can perform. For Blue Sky Robotics’ manufacturing, w

4 min read

Exploring the Best Robotic Arm Kits for Beginners and Professionals

Robotic arm kits offer a hands-on bridge between theoretical robotics and real-world automation, enabling users to assemble, test and program articulated manipulators from the ground up.

4 min read

Understanding End Effectors in Robotics and Automation

End effectors are the hands of robotic systems, responsible for interacting with objects and performing tasks across manufacturing, biomedical and logistics environments. For Blue Sky Robotics’ au dience in the manufacturing, warehousing and automation sectors, understanding these tools is key to deploying flexible, reliable systems that meet production and handling requirements. Advances in modern materials and embedded sensors have increased precision and adaptability, ena

4 min read

Pick and Place Robots: Speed, Precision, and Automation Power

Manufacturers and warehouses increasingly rely on robots to deliver consistent speed and precision on repetitive tasks, transforming throughput and quality control. What began as manual pick-and-place work has evolved into coordinated, high-speed automation that reduces cycle times and lowers error rates across production lines. A modern pick and place robot integrates motion, end-effectors and control logic to replace slow, variable human handling with predictable performanc

4 min read

Universal Robots UR5: The Versatile Collaborative Robot for Automation

The UR5 from Universal Robots has become a go-to collaborative arm for teams that need a flexible, easy-to-integrate solution for light industrial tasks. Known across factories and labs, the universal robots ur5 combines a 5 kg payload with an 850 mm reach, giving manufacturers, warehousing operations and research groups the dexterity to handle assembly, pick-and-place, testing and other repetitive tasks without complex infrastructure changes. As collaborative robots (cobots

3 min read

UR30 Cobot Overview: Power, Reach & Cost

Universal Robots helped make collaborative robots a practical option for manufacturers by combining flexible arm designs with user-friendly programming and integrated safety features that let robots work alongside people. The UR30 cobot pairs a compact footprint with an unusually high payload, offering a balance of power and space efficiency suited to modern production lines. That combination makes it especially relevant to Blue Sky Robotics’ audience in manufacturing, ware

4 min read

Understanding Servo Motors in Modern Automation Systems

A servo motor is a closed-loop actuator that delivers controlled torque and position for precise motion in automation and robotics. Precise motion control is critical in manufacturing, warehousing and industrial robotics, where repeatability, speed and accuracy directly affect product quality and system uptime. For Blue Sky Robotics’ customers, that precision translates into higher throughput, reduced waste and smoother integration with vision and safety systems. This overv

3 min read

Top Robotic Arm Kits for Makers and Professionals

Interest in robotics is accelerating across industry and hobbyist communities as automation becomes both more capable and more affordable. For manufacturing, warehousing and automation professionals at Blue Sky Robotics, hands-on robotic platforms offer a direct way to evaluate new workflows, prototype end-of-arm tooling and train teams without large capital outlays. Robotic arm kits bridge the gap between theory and practice by putting control, sensing and motion into the le

3 min read

Industrial Automation: Systems, Benefits, and Applications

Understanding industrial automation has become essential for manufacturers and warehouses aiming to boost productivity and consistency. Advances in robotics, integrated software, and industrial internet of things platforms are reshaping how production lines run, reducing manual error and increasing throughput. Robotics handle repetitive and hazardous tasks, while software systems coordinate workflows and industrial IoT connects sensors and machines for real-time insight. Th

3 min read

One Robot Many Workflows

Discover how automation in distribution centers allows one robot to handle picking and packing, kitting and assembly, and custom kitting and fulfillment, boosting efficiency and adaptability.

2 min read

bottom of page