top of page

Spray & Adhesive Robotics

Discover the latest in spray and adhesive robotics, including paint robots, spray robots, and powder coating robots. Explore automation for applying adhesives, sealants, and coatings with precision and consistency across industrial workflows.

Painting Robots for Industrial Coating Automation

Industrial painting robots are transforming coating lines across manufacturing, warehousing and automation operations. A painting robot delivers consistent film build and finish quality while speeding cycle times and reducing worker exposure to hazardous materials. For companies in Blue Sky Robotics’ customer base, these systems provide a practical path to higher throughput and tighter quality control. Automation improves coating consistency, production efficiency and wo

4 min read

Fairino FR20: Transforming Industrial Painting with Explosion-Proof Automation

The Fairino FR20’s explosion-proof design makes it ideal for safe, automated painting in hazardous industrial environments.

4 min read

How Spray Robots Handle Part Variability: Cutting Calibration Costs with Smarter Automation

Spray robots have become a cornerstone of robotic finishing and surface finishing automation, offering consistency, efficiency, and safer working environments compared to manual painting.

3 min read

Automated Paint Systems: Overcoming Operational and Business Challenges in Industrial Coating

Automated paint systems have become an essential tool in modern manufacturing.

3 min read

Automated Gluing in Manufacturing: Boosting Precision and Reducing Waste

Across industries, manufacturers are under pressure to assemble and finish products faster, with greater accuracy, and at lower cost. For...

3 min read

Automatic Spray Painting: How to Eliminate Overspray and Improve Coating Consistency

Spray painting is one of the most common finishing processes in manufacturing, but it comes with two major challenges: overspray and inconsistent coatings. These issues drive up costs, increase waste, and put product quality at risk.

3 min read

Robotic Sanding: Transforming Surface Finishing

Learn how robotic sanding and automatic polishing enhance efficiency, safety, and precision in modern manufacturing workflows.

4 min read

How Blue Sky Robotics Uses Human-Centered Design for Automation Solutions

Robotics is transforming industries of every scale. From manufacturing to logistics to custom fabrication, automated systems are no longer limited to massive factories with multimillion-dollar budgets. Today, small and midsize businesses are exploring robotics as a way to increase efficiency, reduce errors, and stay competitive. But the true breakthrough isn’t simply about adding more machines, it’s about designing automation that works with people, not around them.

5 min read

Flexible Automation vs Fixed Systems: Why Small Manufacturers Need Adaptable Solutions in 2025

Traditional fixed automation systems are failing small manufacturers who need adaptability and cost-effectiveness. Flexible automation offers the perfect solution for high-mix, low-volume production environments.

7 min read

How the Blue Sky Paint Robot Compares to ABB, FANUC, Yaskawa, and Kawasaki

While industry giants like ABB, FANUC, Yaskawa, and Kawasaki dominate the market with traditional paint robots, Blue Sky Robotics introduces a different kind of solution: the Blue Sky paint robot powered by the Blue Sky Autocoat System.

3 min read

Intelligent Paint Shops: AI Integration in Robotic Spray Systems

The integration of AI into robotic spray painting systems marks a turning point in manufacturing.

4 min read

Energy‑Efficient Spray Robots: Reducing Paint Waste & Cycle Time

Emerging research and industrial innovations show that subtle changes in robot motion—not just hardware upgrades—can save 20–30% in energy and cycle time without degrading finish quality for robot spray painting.

3 min read

Automating Paint Shops: How Paint Robots Improve Finish and Safety

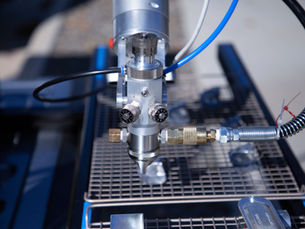

Paint robots are changing the game in industrial finishing. This post dives into how robotic spray systems enhance quality, reduce overspray, and eliminate worker exposure to fumes. We’ll cover key components such as articulated arms, flow regulators, and programmable paths, and how they integrate with safety enclosures or cobot systems for flexibility. Learn how paint robots are used in automotive, furniture, and equipment manufacturing, and what ROI to expect from investing

2 min read

Adhesive Spray Options for Industrial Robot Applications

Adhesive spray for industrial robots plays a critical role in modern automation, enabling precise, durable, and efficient bonding across manufacturing processes. This article explores the main adhesive types—cyanoacrylate, epoxy, acrylic, and polyurethane—highlighting their benefits, selection criteria, and performance in robotic assembly, packaging, welding, and more. Learn how the right adhesive spray improves cycle times, reduces downtime, and boosts product quality in hig

8 min read

Top 10 Painting Robot Arms Powering the Future of Industrial Coating

Robotic painting arms are revolutionizing industries like automotive and electronics by enabling consistent finishes, reduced waste, and efficient production. From flexible six-axis arms to compact cobots and electrostatic sprayers, each type serves a unique purpose in modern automated painting systems. Choosing the right arm is key to optimizing performance and quality in automated coating operations.

4 min read

Revolutionizing the Industry: How Paint Robots Are Transforming Robotic Painting

Robotic painting boosts precision, efficiency, and safety in manufacturing. Used across industries like automotive and aerospace, these systems reduce waste, cut costs, and deliver high-quality finishes.

5 min read

Cobot Painting Integration: Revolutionizing Large-Scale, High-Precision Painting Operations

Collaborative robot painting – or cobot painting integration – is transforming how U.S. industrial companies manage large-scale, high-precision painting tasks. From automotive to aerospace, collaborative painting robots are boosting efficiency, enhancing paint consistency, improving worker safety, and delivering strong ROI.

3 min read

bottom of page