Why Cobots Are the Future of Pick and Place Operations

- Blue Sky Robotics

- Jul 28, 2025

- 2 min read

Updated: Sep 10, 2025

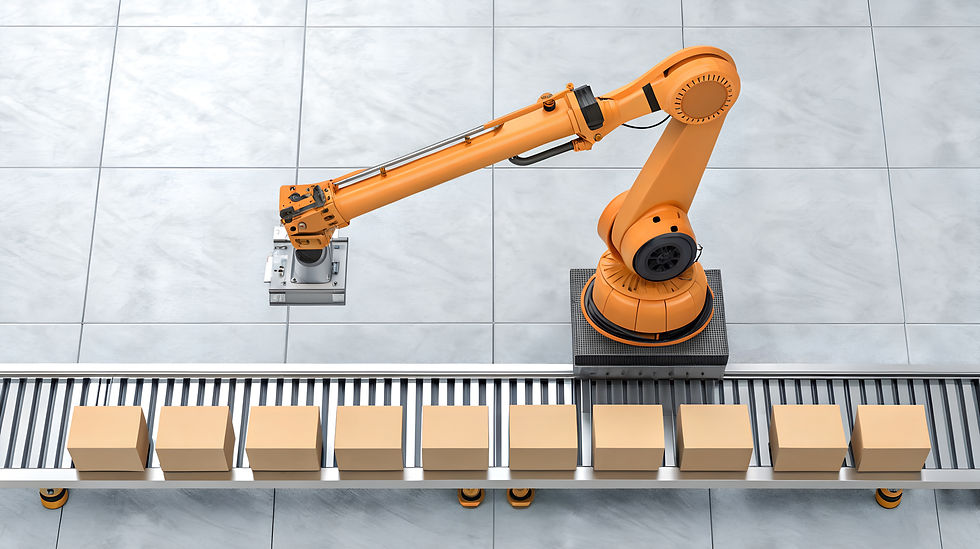

Pick and place operations have long been a major bottleneck in high-volume warehouse environments. As fulfillment demands rise and labor becomes harder to scale, companies are turning to a smarter, safer solution: cobot robotics.

Collaborative robots—or cobots—are transforming the way warehouses approach repetitive tasks like picking, packing, sorting, and kitting. When paired with advanced end effectors (EOATs) and vision systems, cobots offer the precision and flexibility needed for today’s fast-moving supply chains—without compromising on safety or adaptability.

Why Cobots Are a Game-Changer for Pick and Place

Unlike traditional robots, cobots are designed to work with people, not just instead of them. Here’s why they’re becoming the go-to choice for pick and place tasks:

Repetition Without Fatigue: Cobots thrive on repetitive motion—exactly the kind of work that exhausts human workers and leads to errors over time. They can pick, place, and reposition thousands of items per shift without losing speed or accuracy.

Vision-Guided Alignment: Modern cobots integrate seamlessly with cameras and machine vision, allowing them to identify and adjust to variations in product size, shape, or orientation. Whether it’s placing circuit boards or folding apparel, vision-enabled pick and place robots can adapt on the fly.

Safe Human-Robot Collaboration: Equipped with torque sensors and safety-rated software, cobots stop instantly when contact is detected. This allows them to work side-by-side with human teams—no cages or downtime required.

Scalable for Multi-Shift Operations: Unlike manual labor, cobots can run 24/7 with minimal supervision. For facilities managing multiple shifts or peak-season spikes, cobots provide consistent throughput without burnout.

The Power of the Right End Effector

The true versatility of a cobot lies in its end effector—the tool that interfaces with the product. From vacuum grippers for lightweight packaging to adaptive fingers for irregularly shaped parts, choosing the right EOAT is critical to performance.

Vacuum Cups – Ideal for boxes, pouches, and sealed items

Parallel Grippers – Great for rigid, uniform products

Soft Adaptive Grippers – Handle fragile, irregular, or deformable goods

Magnetic or Needle Grippers – For specialty items like textiles or metal parts

With quick-change EOAT systems, cobots can even switch tools mid-shift to handle diverse tasks.

Use Cases in Modern Warehousing

Cobots are already proving their worth in a range of logistics operations:

E-commerce: Automating item picking, sorting, and packing

Retail Distribution: Repetitive case handling for store replenishment

Manufacturing: Kitting and assembly of small components

3PLs: Supporting variable workflows across multiple clients

Their small footprint and flexibility make them ideal for retrofitting into existing operations.

What’s the ROI?

Implementing cobots for pick and place can deliver returns in as little as 12–18 months, depending on task complexity and volume. Key cost-saving and performance benefits include:

Reduced labor dependency

Lower error rates

Shorter cycle times

Increased throughput

Minimal downtime or retraining

Because cobots are programmable with intuitive interfaces, you don’t need robotics experts to manage them—just a well-defined workflow.

Final Thoughts

Cobots represent the next evolution in robotics warehouse operations. They’re not just efficient—they’re collaborative, safe, and incredibly adaptable to the real-world demands of pick and place work.

If you're struggling with labor gaps, rising SKUs, or fulfillment bottlenecks, cobot robotics—combined with the right end effector—can bring the precision, reliability, and ROI you need to stay competitive.

Get in touch with Blue Sky Robotics today and see what robotics can do for your warehouse.