top of page

Energy‑Efficient Spray Robots: Reducing Paint Waste & Cycle Time

Emerging research and industrial innovations show that subtle changes in robot motion—not just hardware upgrades—can save 20–30% in energy and cycle time without degrading finish quality for robot spray painting.

3 min read

Automating Paint Shops: How Paint Robots Improve Finish and Safety

Paint robots are changing the game in industrial finishing. This post dives into how robotic spray systems enhance quality, reduce overspray, and eliminate worker exposure to fumes. We’ll cover key components such as articulated arms, flow regulators, and programmable paths, and how they integrate with safety enclosures or cobot systems for flexibility. Learn how paint robots are used in automotive, furniture, and equipment manufacturing, and what ROI to expect from investing

2 min read

Adhesive Spray Options for Industrial Robot Applications

Adhesive spray for industrial robots plays a critical role in modern automation, enabling precise, durable, and efficient bonding across manufacturing processes. This article explores the main adhesive types—cyanoacrylate, epoxy, acrylic, and polyurethane—highlighting their benefits, selection criteria, and performance in robotic assembly, packaging, welding, and more. Learn how the right adhesive spray improves cycle times, reduces downtime, and boosts product quality in hig

8 min read

Affordable Robotic Arms: How Advanced Manufacturing and Streamlined Supply Chains Are Revolutionizing Robotics

In recent years, the robotics industry has undergone a remarkable transformation, making robotic arms more affordable and accessible than ever before. This breakthrough is primarily driven by advancements in manufacturing technologies and a streamlined supply chain that cuts costs without compromising quality. Affordable robotic arms are now empowering small and medium-sized businesses across diverse industries—from automotive and electronics to consumer goods and healthcare.

5 min read

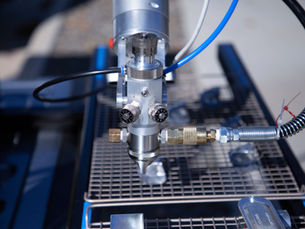

Robotic End of Arm Tooling: Styles, Prices, and What to Know Before You Buy in the EOAT World

Investing in automation means making informed decisions—especially when it comes to robotic end of arm tooling. Also known as robotic...

2 min read

End Effector Types Explained: Choosing the Right Robotic EOAT for Your Application

In modern automation, selecting the right robot end effector can make or break the performance of your robotic system. Often referred to as robotic EOAT (End of Arm Tooling), end effectors are the tools attached to the end of a robot arm that interact with the environment to perform tasks like gripping, welding, cutting, or moving parts. But not all end effector types are created equal. Below, we break down common end effector types, their best applications, and real-world us

2 min read

Revolutionizing the Industry: How Paint Robots Are Transforming Robotic Painting

Robotic painting boosts precision, efficiency, and safety in manufacturing. Used across industries like automotive and aerospace, these systems reduce waste, cut costs, and deliver high-quality finishes.

5 min read

Cobot Painting Integration: Revolutionizing Large-Scale, High-Precision Painting Operations

Collaborative robot painting – or cobot painting integration – is transforming how U.S. industrial companies manage large-scale, high-precision painting tasks. From automotive to aerospace, collaborative painting robots are boosting efficiency, enhancing paint consistency, improving worker safety, and delivering strong ROI.

3 min read

Beyond the Bot Ep. 5: Justin Lorenzo, L&M Architectural Signs, and Manufacturing Automation

Tony DeHart talks with Justin Lorenzo, President of L&M Architectural Signs, about how a multi-generational, family-run signage business is transforming with automation. Justin shares how his team embraced robotic painting technology not only to boost efficiency but to elevate quality—meeting the intense demands of modern manufacturing without compromising on craftsmanship. From early challenges to impressive ROI, they explore what it really means to merge tradition and innov

7 min read

bottom of page